Waa maxay daaweynta induction?

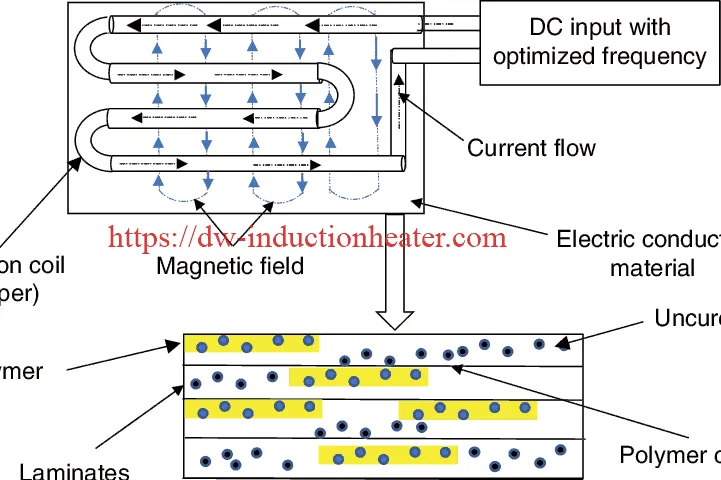

Sidee buu u shaqeeyaa daawaynta induction? Si fudud loo dhigo, awoodda xadhkaha ayaa loo beddelaa hadda beddelka ah waxaana la geeyaa gariiradda shaqada taasoo abuurta goob koronto-magneteedka gudaha gariiradda. Qaybta epoxy-ga ku dul taal waxay noqon kartaa bir ama semiconductor sida kaarboon ama garaafka. Si loo daaweeyo epoxy substrates-ka aan shaqayn sida dhalada, dabci koronto leh ayaa loo isticmaali karaa in lagu wareejiyo kulaylka walxaha aan shaqaynayn.

Waa maxay faa'iidooyinka daaweynta kicinta?

Xabagta epoxy-ga oo ka kooban hal unug oo kulaylka la daaweeyay waxay isticmaali karaan kulayl ilo kala duwan. Midda ugu caansan waa foornada laakiin qoryaha hawada kulaylka, taarikada dubista iyo daawaynta induction ayaa sidoo kale la isticmaalaa. Daawaynta soo-jiidashada waxay si weyn u yareeyn kartaa cadadka wakhtiga loo baahan yahay si loo daweeyo epoxy-ka oo la yareeyo saamaynta kulaylka qaybaha ku xeeran maadaama kuleyliyaha induction uu si sax ah u gaarsiiyo kulaylka aagga koollada.

Daawaynta induction miyay u tahay dookh wanaagsan codsigeyga?

Bixinta kaaga Qalabka kululeynta la-galinta takhasuska leh iyo macluumaadka soo saaraha epoxy-ga ee mawduucyada soo socda ayaa ka caawin doona inay sameeyaan talada ugu fiican.

1. Alaabta ama substrate-ka la isku xidhay - Fahamka waxa substrates-ku waxa ay caawinaysaa in la go'aamiyo heerka kulaylka iyo awooda loo baahan yahay si loo daweeyo koolada. Tusaale ahaan kulaylka birta oo leh awood ka yar inta loo baahan yahay si loo kululeeyo aluminium.

2. Baaxadda qaybaha la isku xidhay - Qaybaha yaryar waxay u baahan yihiin soo noqnoqoshada sare ee kuleyliyaha waxtarka leh. Meelaha waaweyni waxay ka faa'iidaystaan soo noqnoqoshada hoose.

3. Shuruudaha Epoxy - Waxaa jira ugu yaraan/max marin loogu talagalay daawaynta epoxy. Heerkulka ugu yar ee loo baahan yahay si loo hirgeliyo daaweynta iyo heerkulka ugu sarreeya ee la oggol yahay ka hor burburka epoxy-ga.

Daawaynta Soo-gelinta ee Ku-xidhka Chip-ka Quartz ee Silinder-Birta

Shirkad ku jirta warshadaha Baabuurta ayaa raadinaysa habka kuleylinta induction kaas oo gaari kara heerkulka 175°C (347°F) oo ku xajin kara dulqaadka adag ee +/- 3 C. Kuleylka induction waxay kululeyn doontaa dhululubada birta si ay u daaweyso koolada isku xirka chip quartz. Kuleyliyaha kicinta waa habka la door bidayo sababtoo ah waxay bixisaa kuleyl degdeg ah, la kontaroolo oo labis ah.

Warshadaha: Automotive

Qalabka: DW-UHF-10kW nidaamka kuleylka kuleylka waxaa lagula talinayaa in codsigan daawaynta kor loogu qaado oo uu hayo heerkulka la rabo.

Geedi socodka:

Hadafka codsigan daawaynta induction waa in la kululeeyo labada dhinac ee dhululubada birta ah kaas oo ah 1.064” (2.70 cm) OD, 7.25” (18.41 cm) oo dheer oo leh 1” (2.54 cm) aagga kulaylka ilaa 175C F) oo ku hay heerkulkaas 347 ilbiriqsi si aad u samayso codsiga isku xidhka. Heerkulkii la rabay waxaa lagu gaaray 60 ilbiriqsi. Xakamaynta heerkulka nooca K ayaa loo adeegsaday cabirka heerkulka.

Daawaynta Soo-gelinta ee Ku-xidhka Chip-ka Quartz ee Silinder-Birta