Nidaamka kululaynta firfircoonida magnetic

Description

Nidaamka kuleylka ee kuleylinta induction magnetic IGBT

Astaamaha ugu muhiimsan:

- Qalabka IGBT iyo casriyeynta teknooloojiyada, waxqabadka wanaagsan, kalsooni sarreeya qiimaha dayactirka;

- 100% wareega shaqada, shaqeyn joogto ah ayaa loo ogolyahay soo saarka awoodda ugu badan;

- Xaalad awood joogto ah oo joogto ah ama joogto ah ayaa loo xulan karaa si loo gaadho waxtarka kuleylka sare;

- muujinta tamarta kuleylka iyo kuleylka kuleylka iyo kuleylka;

- farsamooyin badan oo muuqaal ah, oo leh bandhigyo badan oo ka sarreeya, koronto la'aan, fashilaadda biyaha, fashil la'aanta iyo ladnaanta aan fiicnayn iyo wixii la mid ah, mashiinka ayaa laga ilaalin karaa burburinta iyo mashiinnada si fudud ayaa loo hagaajin karaa.

- si fudud oo loo rakibo, rakibidda waxaa sameeya qof aan xirfadlaha aheyn si fudud, biyaha iyo awoodda ayaa la dhameyn karaa daqiiqado yar gudahood.

- miisaanka yar, cabbirka yar.

- qaab iyo cabir kala duwan kululaynta kuleylka induction si fudud ayaa loo beddeli karaa si loo kululeeyo qaybo kala duwan.

- Faa'iidooyinka qaabka leh saacad: Awoodda iyo wakhtiga hawlgalka wakhtiga kuleylka iyo muddada heynta waxaa loo kala hormarin karaa, si loo ogaado qalabka kuleylka fudud, qaabkani waxaa lagu talinayaa in loo isticmaalo wax soo saarka si loo hagaajiyo soo celinta.

- moodooyinka kala gooni ah ayaa loogu talagalay inay ku habboonaadaan nadiifinta hareeraha, koronto-dhaliyaha waxaa lagu gelin karaa meel nadiif ah si loo kordhiyo kalsoonida; oo leh miisaan yar iyo miisaan fudud oo ka mid ah tamarta kala-gooni ah, waxaa habboon in la isticmaalo khadka wax soo saarka iyo si sahlan loogu soo ururiyo gudaha mishiinada ama farsamooyinka dhaqaaqay.

| Taxanaha | model | Awooda gelitaanka Max | Iminka Max | Joogitaanka Oscillate | danab Input | Wareegga shaqada | |

| MF

. |

DW-MF-15 Induction Generator | 15KW | 23A | 1KHz-20KHz Sida ku cad codsiga | 3phases380V ± 10% | 100% | |

| DW-MF-25 Induction Generator | 25KW | 36A | |||||

| DW-MF-35Induction Generator | 35KW | 51A | |||||

| DW-MF-45 Induction Generator | 45KW | 68A | |||||

| DW-MF-70 Induction Generator | 70KW | 105A | |||||

| DW-MF-90 Induction Generator | 90KW | 135A | |||||

| DW-MF-110 Induction Generator | 110KW | 170A | |||||

| DW-MF-160 Induction Generator | 160KW | 240A | |||||

| DW-MF-300 Induction Generator | 300KW | 400A | |||||

| DW-MF-45 Induction Iskeelitir kuleylka Qodobka Foornada | 45KW | 68A | 1KHz-20KHz | 3phases380V ± 10% | 100% | ||

| DW-MF-70 Induction Iskeelitir kuleylka Qodobka Foornada | 70KW | 105A | |||||

| DW-MF-90 Induction Iskeelitir kuleylka Qodobka Foornada | 90KW | 135A | |||||

| DW-MF-110 Induction Iskeelitir kuleylka Qodobka Foornada | 110KW | 170A | |||||

| DW-MF-160 Uku Kuleylka Kuleylka Kuleylka Foornada | 160KW | 240A | |||||

| DW-MF-15 Foornada dhalaalida dhalaalka | 15KW | 23A | 1K-20KHz | 3phases380V ± 10% | 100% | ||

| DW-MF-25 Foornada dhalaalida dhalaalka | 25KW | 36A | |||||

| DW-MF-35 Foornada dhalaalida dhalaalka | 35KW | 51A | |||||

| DW-MF-45 Foornada dhalaalida dhalaalka | 45KW | 68A | |||||

| DW-MF-70 Foornada dhalaalida dhalaalka | 70KW | 105A | |||||

| DW-MF-90 Foornada dhalaalida dhalaalka | 90KW | 135A | |||||

| DW-MF-110 Foornada dhalinta dhalaalaysa | 110KW | 170A | |||||

| DW-MF-160 Foornada dhalinta dhalaalaysa | 160KW | 240A | |||||

| Qalabka DW-MF-110 Qalabka Dheeraynta | 110KW | 170A | 1K-8KHz | 3phases380V ± 10% | 100% | ||

| Qalabka DW-MF-160Iuction Qalabka adag | 160KW | 240A | |||||

| HF

. |

DW-HF-15 Series | DW-HF-15KW | 15KVA | 32A | 30-100KHz | Xaaladda Hal 220V | 80% |

| DW-HF-25 Series | DW-HF-25KW-A | 25KVA | 23A | 20K-80KHz | 3phases380V ± 10% | 100% | |

| DW-HF-25KW-B | |||||||

| DW-HF-35 Series | DW-HF-35KW-B | 35KVA | 51A | ||||

| DW-HF-45 Series | DW-HF-45KW-B | 45KVA | 68A | ||||

| DW-HF-60 Series | DW-HF-60KW-B | 60KVA | 105A | ||||

| DW-HF-80 Series | DW-HF-80KW-B | 80KVA | 130A | ||||

| DW-HF-90 Series | DW-HF-90KW-B | 90KVA | 160A | ||||

| DW-HF-120 Series | DW-HF-120KW-B | 120KVA | 200A | ||||

| DW-HF-160 Series | DW-HF-160KW-B | 160KVA | 260A | ||||

| UH

. F .

|

DW-UHF-4.5KW | 4.5KW | 20A | 1.1-2.0MHz | Hal waji ah 220V ± 10% | 100% | |

| DW-UHF-6.0KW | 6.0KW | 28A | |||||

| DW-UHF-10KW | 10KW | 15A | 100-500KHz | 3phases380V ± 10% | 100% | ||

| DW-UHF-20KW | 20KW | 30A | 50-250KHz | ||||

| DW-UHF-30KW | 30KW | 45A | 50-200KHz | ||||

| DW-UHF-40KW | 40KW | 60A | 50-200KHz | ||||

| DW-UHF-60KW | 60KW | 90A | 50-150KHz | ||||

Codsiyada

1. Kuleylka (foojignaan kulul, kuleyl kulul iyo dhalaal)

Induction Ku shubashada kulul ujeedadeedu tahay in lagu been abuuro qaybaha shaqada ee heerkulka qaarkood (qalab kala duwan ayaa u baahan heerkul kala duwan) qaabab kale iyada oo loo marayo saxaafadda been abuurka ah iyadoo gacan laga helayo qalabka foojarka, mashiinka been abuurka ama qalab kale, tusaale ahaan, fidinta kulul ee kiiska saacadda, garabka saacadda, qabashada, caaryada qalabka, jikada iyo miiska, qalabka farshaxanka, qaybta caadiga ah, dhejiska, qayb farsamo oo la alifay, qufulka naxaasta, rivet, biinanka birta iyo pin.

Rakibidda kuleylka waxaa loola jeedaa isku xirnaanta biraha kala duwan ama biraha aan birta ahayn iyada oo loo marayo kuleylka iyada oo ku saleysan mabda'a ballaarinta kuleylka ama dhalaalka kulul, tusaale ahaan, alxanka gundhig ee udubdhexaadka naxaasta ee hiitarka kumbuyuutarka ee leh aluminium iyo websaydhada hadalka, iskudhafka birta iyo caagga tuubada, qufulka aluminium aluminium (diirka diirka iligga), rotor matoor iyo xiritaanka walxaha kuleylka korontada ku shaqeeya.

Dheehitaanku badanaa wuxuu ujeedkiisu yahay inuu biraha ugu dhalaaliyo dareere iyadoo la adeegsanayo heerkulka sare, kaas oo inta badan khuseeya dhalaalida birta, birta, naxaasta, aluminium, zinc iyo sidoo kale biro kala duwan oo sharaf leh.

Daaweynta kuleylka (dusha dabka)

Demi qalabka iyo qalabka kala duwan, sida qalabka wax lagu duubo, khafiifka, dubbe, faashka, qalabka wax lagu xiro iyo xiirista (jeexjeexa beeraha).

Demi qalabka gawaarida iyo mootooyinka kala duwan, sida crankshaft, isku xirka ul, pin piston, silsilad wheel, aluminium wheel, waalka, usheeda dhexe gacanta, usheeda dhexe drive, usheeda dhexe yar iyo fargeeto. Qalabka korontada oo kala duwan, sida qalabka iyo faashash.

Demi qalabka mashiinka, sida sagxadda lathe iyo tareenka hagaha.

Demi qaybaha birta qalabka kala duwan iyo qaybaha mashiinka, sida usheeda dhexe, marsho (silsilad wheel), cam, chuck iyo clamp iwm.

Demi for wasakhahaasi hardware, sida caaryada-size yar yar, caaryada siyaada ah iyo daloolka hoose ee caaryada.

3. Alxanka (alxanka, alxamid lacag, iyo brazing)

Alxanka qalabka kala duwan ee qalabka wax lagu jaro, sida qalabka dheemanka, aaladda la xoqin karo, qalabka wax lagu qodo, qalabka wax lagu gano, qalabka wax lagu gooyo, qalabka wax lagu jaro, qalabka wax lagu jaro, qalabka wax lagu qoro, qalabka wax lagu qorsheeyo iyo xarunta dhexe ee adag.

Alxanka of qalab farsamo qalab kala duwan: Alxanka iyo brazing induction oo ah biro isku nooc ah ama noocyo kala duwan ah, sida musqusha qalabka iyo alaabada jikada, qaboojiyaha ku xirida naxaasta, ku xirnaashada qurxinta laambada, saxsanaanta caaryada, maareynta qalabka, eggbeater, birta iyo birta birta, birta iyo naxaasta iyo sidoo kale naxaas iyo naxaas.

Dhexgalka alxanka hoose alxanka ayaa inta badan lagu dabaqi karaa alxanka geesaha ee wareega, laba jibbaaran iyo sidoo kale salka kale ee caadiga ah ee aan caadiga ahayn. Waxa kale oo lagu dabaqi karaa alxanka caadiga ah ee biraha kale.

Alxanka qalabka kululeeyaha ee biyo kululeynta korontada inta badan waxaa loola jeedaa alxanka naxaasta ee birta birta ah ee birta ah, xaashida aluminium iyo walxaha kuleylka korontada ku shaqeeya ee qaabab kala duwan leh

3.Anealing (xanaaq iyo isbadal)

Kireynta alaabooyinka birta ah ee kala duwan, sida weelka birta ah ee birta ah, annealed iyo extruded qasac, annealedled gees, saxanka annealed, tuubada birta ahaanta, weelka miiska iyo koobka.

Daahfurka qaybaha kale ee shaqada ee biraha, sida madaxa kubbadda golf, calaamadda, qufulka naxaasta, qalabka korontada ku xirma, qalabka mindida jikada, daab, aluminium digsiga, baararka aluminium, hiitarka aluminium iyo alaabooyin kala duwan oo aluminium ah.

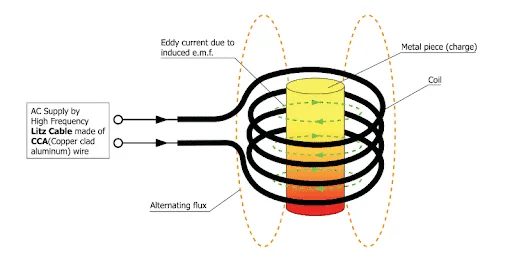

Mabaadi'da Is-beddelka Kororka

Isbedelka isbeddelka kuleylka kuleylka (electromagnetic induction) ama kuleylinta induction ee gaaban waa hab lagu kululeeyo qalabka biraha iyada oo loo rogayo korantada korantada korantada tan mid kala duwan oo gaar ah iyada oo ku saleysan mabda'a soo saarista elektromagnetic. Waxay badanaa ku habboon tahay birta shaqada kulul, daaweynta kuleylka, alxanka iyo dhalaalida. Farsamadan kuleylka ah ayaa sidoo kale lagu dabaqi karaa warshadaha wax lagu duubo (sida shaabadaynta aluminium aluminium ee loo isticmaalo daawada iyo warshadaha cuntada), qalabka semiconductor (sida silsiladda monocrystalline-ka ee la soo saaray iyo qaybaha biraha ee kuleylka kulul).

Nidaamka kuleylka kuleylka ee aasaasiga ah waxaa ka mid ah gariiradda soo-dhexgalka, isha korantada AC iyo qaybaha shaqada. Isku-xidhka soo-saarka ayaa lagu been-abuuri karaa qaabab kala duwan sida walxaha kulul ee kala duwan. Gariiradda waxay kuxirantahay ilaha korontada ee bixisa isbeddelka hadda ee gariiradda Kala-beddelka isbeddelka leh ee uu leeyahay gariiradda ayaa abuuri kara aag magnet ah oo soo dhex mara qaybaha shaqada si loo soo saaro qulqulka qulqulka sida loogu baahan yahay kuleylka.

Faa'iidooyinka nidaamka kuleylka kuleylka kuleylka

- Kuleylka oo kulul: heerka ugu yar ee kululaynta waa in ka yar 1 sekan (heerka kuleylka waxaa loo heli karaa hagaajin iyo xakameyn).

- Caymiska ballaaran ee kululaynta: waxaa loo isticmaali karaa in lagu kululeeyo qeybaha kala duwan ee birta (beddel cirifka soo-saarista la saari karo sida ku xiran qalabka kaladuwan ee kala duwan).

- rakibaadda Easy: waxaa loo isticmaali karaa mar haddii ay ku xiran tahay isha korontada, isku-xidhka soo-baxa iyo sidoo kale tuubbada biyaha siisa iyo tuubbada soo baxda; way yartahay culeyskiisuna waa fudeyd.

- Hawlgab sahlan: waxaad baran kartaa inaad ku shaqeyso dhowr daqiiqo gudahood.

- Bilaabid degdeg ah: waxaa lagu bilaabi karaa in lagu sameeyo hawlgal kuleylineed iyadoo shuruud looga dhigayo in biyo iyo koronto la helo.

- isticmaalka awoodda Low: Marka la barbardhigo qalabka caadiga ah ee tuubbada faakiyuumka, waxay badbaadin kartaa awoodda qiyaastii 70%. Cabirka yar ee shaqada ayaa ah, isticmaalka tamarta hooseeya ayaa noqon lahaa.

- Waxtarka sare:waxay leedahay astaamo sida kuleylka isku midka ah (waa lagu dabaqi karaa si loo hagaajiyo kala-soocida qulqulka indho-indheynta si loo hubiyo heerkulka ku habboon ee looga baahan yahay qayb kasta oo ka mid ah qaybta shaqada), diirimaad deg deg ah iyo qulqulo xaddidan oo xaddidan, oo ka ilaalin kara qashinka wixii ka dambeeya ka dib.

- Ilaalin dhammaystiran:waxay leedahay shaqooyin noocan oo kale ah cadaadis saa'id ah, xad dhaaf ah, kuleyl badan iyo astaamaha alaarmiga biyo yaraanta iyo sidoo kale xakameyn otomaatig ah iyo ilaalin.

- Heerkulka la xakamayn karo: waa ku habboon tahay in la xakameeyo heerkulka kuleylka qaybaha shaqada sida ku xusan waqtiga kuleylka hore, oo markaa lagu xakameeyo heerkulka kuleylka meel farsamo gaar ah.

- Naqshad dhammaystiran oo buuxa: wuxuu si joogto ah u shaqeyn karaa 24 saacadood.

- Cabbir yar iyo miisaan fudud: waxay leedahay culeys kaliya dhowr daraasiin kiilogaraam, oo ka mid ah, oogada dhulka oo kooban ay si wax ku ool ah u badbaadin karto goobta aqoon isweydaarsiga.

- Ka takhalusida danab sare: uma baahna tarjumaad tallaabo-qaad ah oo soo saari kara qiyaastii toban kun oo danab, oo markaa hubin kara nabadgelyada ugu badan.