Kuleylka kuleylka kuleylka kuleylka ee foojarka

Description

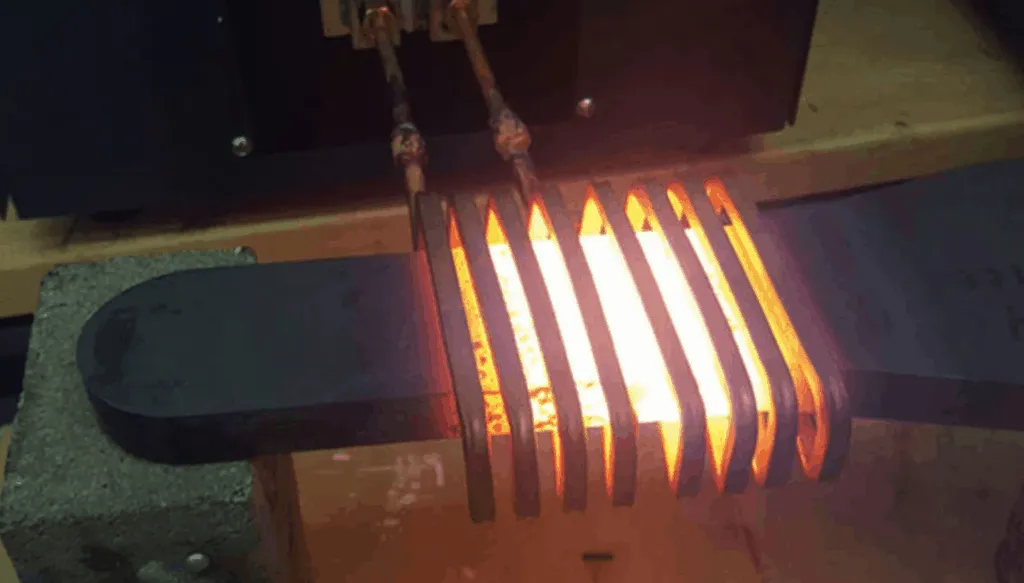

Kuleylka kuleylka kuleylka ee kuleylka ah ee foojarka iyo abuuritaanka kulul

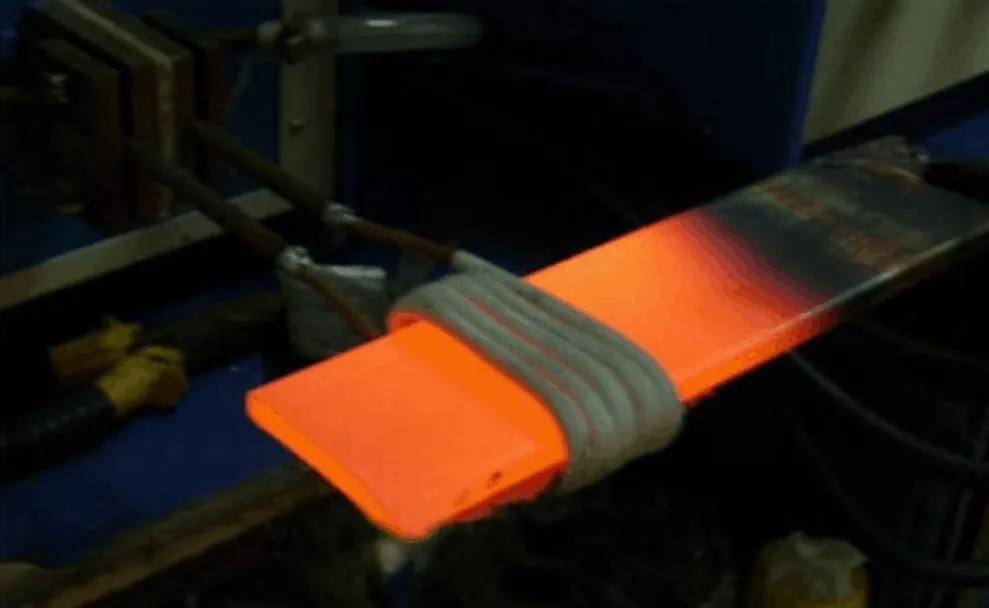

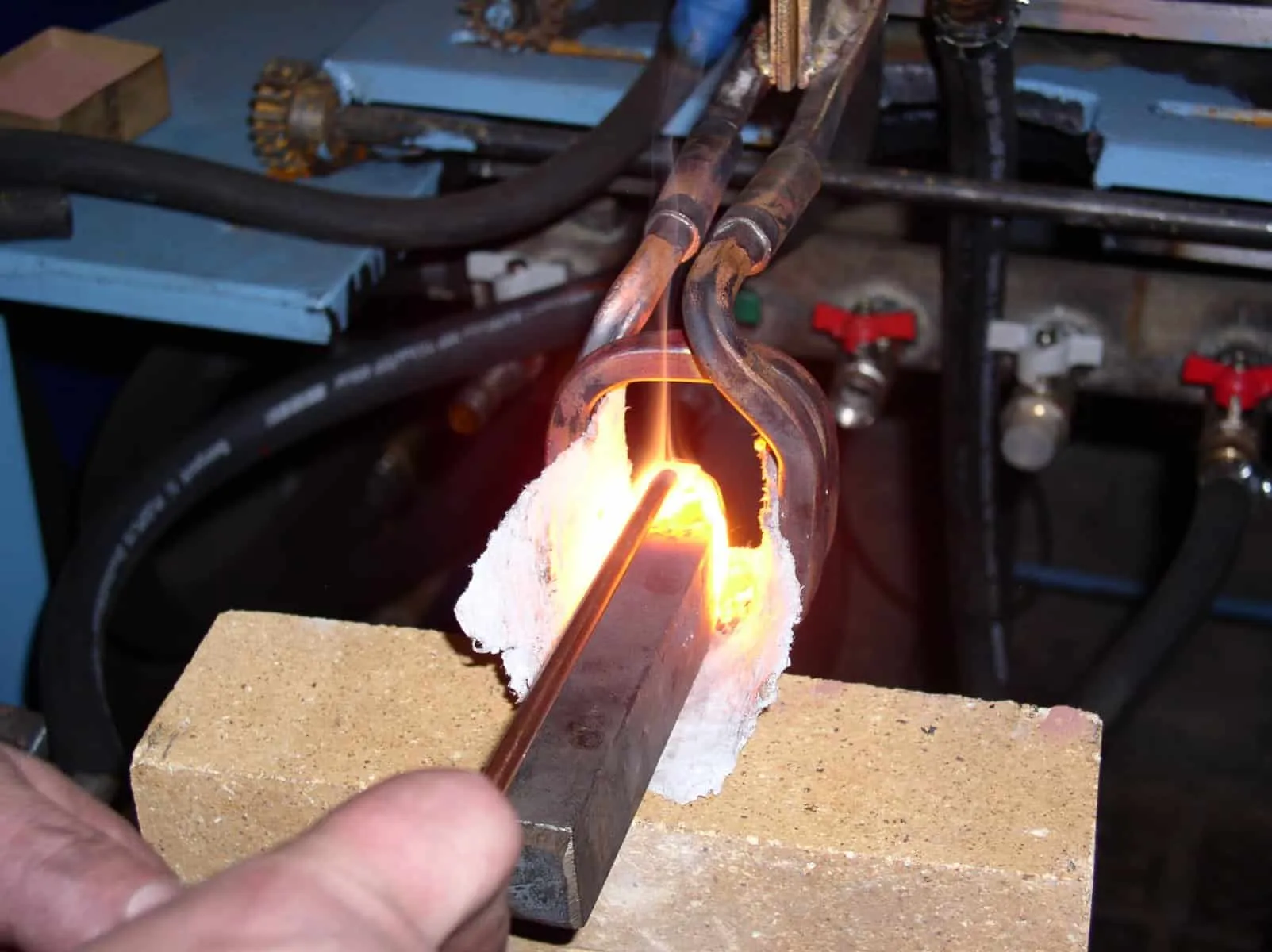

Birta kuleylka kuleylka kuleylka ee birta kuleylka ah iyo qaabeynta kulul waa codsiyada kuleylka kuleylka kuleylka ah. Warshadeed Indho-indheynta foosha iyo sameynta kulul habsocodku waxay ku lug leeyihiin foorarsiga ama qaabeynta bille bir ama ubax ka dib markii lagu kululeeyo heer kul heer ay iska caabbinta cilladdu daciif tahay. Walxaha walxaha aan birta ahayn ayaa sidoo kale la isticmaali karaa.

Mashiinnada kuleylka ee induction ama foornooyinka caadiga ah waxaa loo isticmaalaa hawsha kuleylka bilowga ah. Billet-ka waxaa lagu gayn karaa qalabka diyaaradda iyadoo la adeegsanayo mashiinka neef-mareenka ama hawo-hayaha; qanjaruufo jajab; wadista taraafikada; ama laambadda socodka. Qalab-biyoodka aan lala xiriirin ayaa loo isticmaalaa in lagu cabbiro heerkulka billet.

Mashiinnada kale sida riixayaasha mashiinka waxyeelleeya, mashiinada foorarsiga, iyo mashiinnada fidinta bey'ada waxaa loo isticmaalaa in loo leexiyo ama loo qaabeeyo birta.

Ujeeddo: Preheat saxan bir ah (3.9 "x 7.5" x 0.75 "/ 100mm x 190mm x 19mm) ka hor intaan la abuurin si loo abuuro madax cirif leh hadafka ah kordhinta wax soo saarka marka la barbardhigo kuleylka foornada gaaska.

Waxyaabaha: Birta birta

Heerkulka: 2192 ºF (1200 ºC)

Joogtaynta: 7 Khz

Qalabka kuleylka kuleylka: DW-MF-125/100, 125 kW nidaamka kuleylka induction ku qalabeysan xarun kuleyl fog oo ka kooban seddex 26.8 μF capacitors.

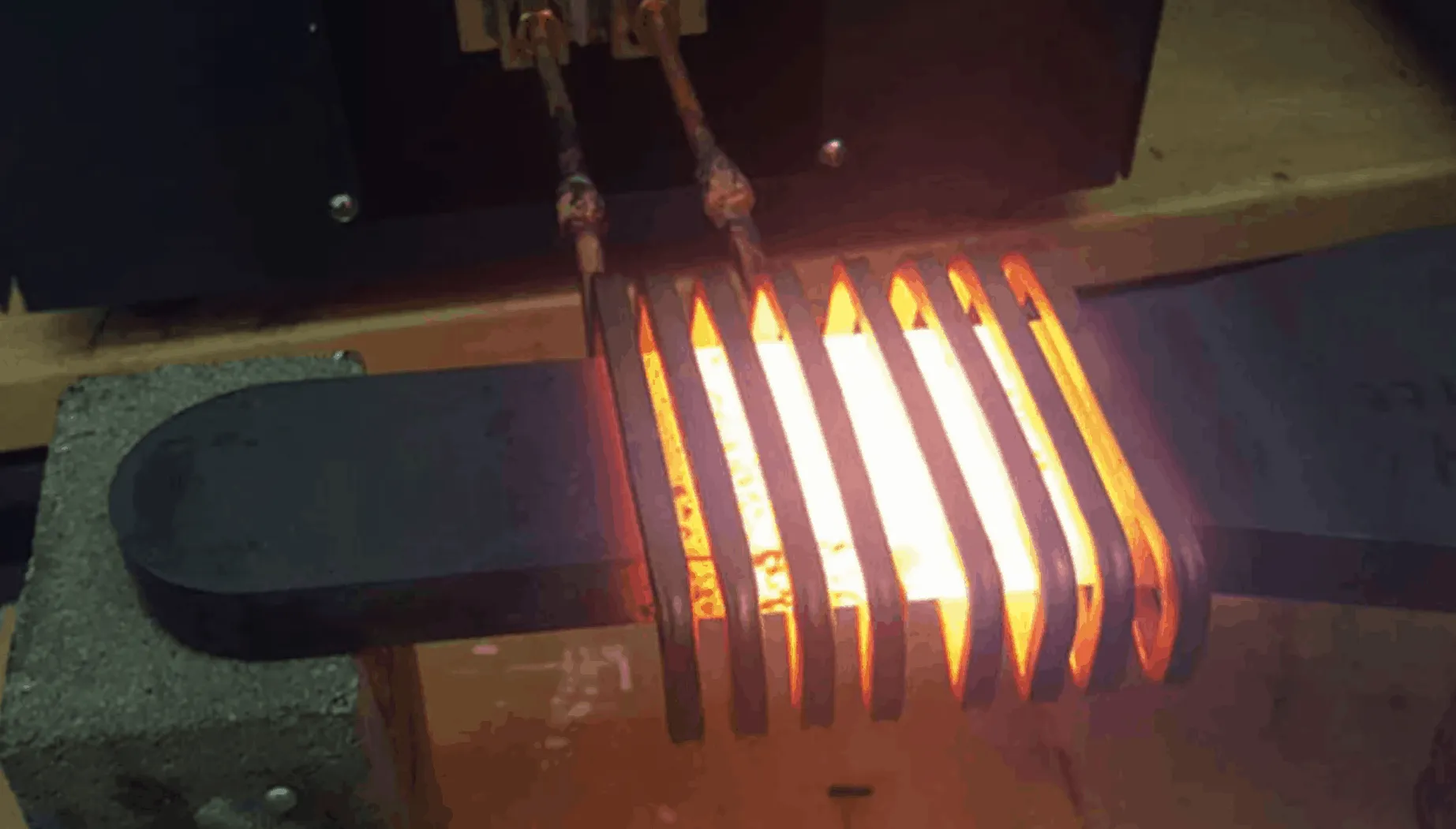

- Saddex meel, isku duubni badan oo kaladuwan oo loogu talagalay loona sameeyay si loo soo saaro kuleylka looga baahan yahay codsigan.

Geedi socodka Taarikada birta ah waxaa la galiyay saddexda meelood ee isku duuban oo hebal ah korantada ayaa la daaray. Markay ahayd 37 ilbidhiqsi, saxan bir labaad oo bir ah ayaa la geliyay, 75 ilbidhiqsi ayayna noqotay saxan saddexaad oo bir ah oo aan lahayn. 115 ilbidhiqsi, heerkulka la rabay ayaa lagu gaadhay qaybta hore, hawshiina way sii socotay.

Bilaabashada kadib, qaybaha waa la kululayn karaa 37-kii ilbiriqsi kasta marka loo eego taxanaha ay soo galeen. Halka wadarta waqtiga wareega uu yahay 115

ilbiriqsiyo, qayb ayaa laga saari karaa 37-kii ilbiriqsi kasta, taas oo u oggolaatay soo-kicinta si loo gaaro heerka wax-soo-saarka la doonayo

iyo in la ogaado faa'iidooyin badan marka la barbar dhigo isticmaalka foornada gaaska.

Natiijooyinka / Faa'iidooyinka

Heerka waxsoosaarka sareeya: Nidaamku wuxuu kudhacay heerka waxsoosaarka 100 qaybood saacaddii, halka foornada gaaska ay soo saartay 83 qaybood saacaddii

- Soo noqnoqoshada: Nidaamkani waa mid la soo celin karo oo lagu dhex dari karo geedi socod wax soo saar

- Sax iyo hufnaan: Kulaylku waa mid sax ah oo hufan, oo leh kuleylka oo keliya lagu dhejiyo taarikada birta

Qiyaasta heerkulka kulaylka ee heerkulka warshadaha ee ugu badan ee la isticmaalo waa:

• Xashiishka 1200º C • Bambo 750º C • Aluminium 550º C

Wadarta Codsiyada Foomka Kuleylka Kuleylka ah

Mashiinnada kuleylinta qulqulatooyinka waxaa badanaa loo isticmaalaa inay kululeeyaan bir bir-bir, baararka, baararka naxaasta ah, iyo alwaaxyada birta ah ee kuleylka saxda ah ee sameynta iyo sameynta kulul.

Codsiyada Qaabaynta Qayb ahaan

Kuleylka kuleylka ayaa sidoo kale loo isticmaalaa in lagu kululeeyo qeybaha sida tuubooyinka tuubooyinka, dhammaadka faashad, qeybaha gawaarida, iyo dhamaadka qeyb ka sameynta iyo sameynta howlaha.

Faa'iidada kuleylka kuleylka

Markii la barbar dhigo foornooyinka caadiga ah, mashiinada kuleylinta soojiidashadu waxay bixiyaan adeegyo muhiim ah iyo faa'iidooyin tayo leh:

Waqtiyada kuleylka gaagaaban oo gaagaaban, yareynta xoqidda iyo urinta jirka

Xakameynta heerkulka heerkulka fudud oo sax ah. Qaybo ka mid ah heerkulka ka baxsan faahfaahinta waa la ogaan karaa waana laga saari karaa

Waqti looma luminayo sugitaanka foornada si ay ula soo baxdo heerkulka loo baahan yahay

Automated Mashiinada kululaynta induction waxay u baahan tahay shaqo gacmeed ugu yar

Kuleylka waxaa loo tilmaami karaa hal qodob oo gaar ah, kaasoo aad ugu muhiim ah qeybaha leh hal aag oo sameysmaya.

Waxtarka kuleylka ee ka weyn - kuleylka ayaa lagu soo saaraa qaybta lafteeda umana baahna in lagu kululeeyo qol weyn.

Xaaladaha shaqo ee ka wanaagsan. Kuleylka kaliya ee hawada ku jira waa kan qaybaha laftooda. Xaaladaha shaqada ayaa aad uga fiican marka loo eego foornada shidaalka.