Cadaadiska Warshadaynta Warshadaynta leh

Description

Cadaadiska Warshadaynta Warshadaynta leh

sooc

1 HADDII DHISMAHA CALAAMADAHA MAGAALADA MAGAALADA,

2 Warshad samafal,

3 Warshad lagu iibiyo,

4 Warshadaha daaweynta kuleylka,

| awoodda lagu qiimeeyo | KG | 10-50 | 100 | 150 | 250 | 350 | 500 | 750 | 1000 | 1500 |

| awood qiimeeyay | KW | 50 | 100 | 100 | 130 | 180 | 250 | 450 | 600 | 1000 |

| danab gelin | V | 380 | 380 | 380 | 380 | 380 | 380 | 380 | 380-2 | 380-2 |

| Awooda tarbuunka | KVA | 60 | 120 | 120 | 150 | 200 | 315 | 500 | 800 | 1500 |

| Awoodda dibadda | V | 750 | 750 | 750 | 750 | 750 | 750 | 1500 | 2500 | 2500 |

| inta jeer ee wax soo saarka | KHZ | 2.5 | 1 | 1 | 1 | 1 | 1 | 1 | 0.8 | 0.8 |

| Waqtiga ereyga | Min | 10-40 | 10-40 | 20-50 | 20-50 | 20-50 | 20-50 | 25-55 | 30-60 | 30-60 |

| Isticmaalka tamarta (birta) | Kw.h / T | 900 | 850 | 850 | 800 | 750 | 700 | 650 | 620 | 600 |

| Isticmaalka tamarta (birta dhagax) | Kw.h / T | 850 | 800 | 800 | 750 | 700 | 650 | 630 | 610 | 580 |

| Isticmaalka tamarta (copper) | Kw.h / T | 500 | 500 | 500 | 490 | 480 | 480 | 400 | 390 | 380 |

| Isticmaalka tamarta (aluminium) | Kw.h / T | 780 | 750 | 750 | 710 | 670 | 620 | 600 | 570 | 540 |

| Qaboojinta biyaha | T / h | 3 | 5 | 5 | 7 | 8 | 10 | 15 | 18 | 25 |

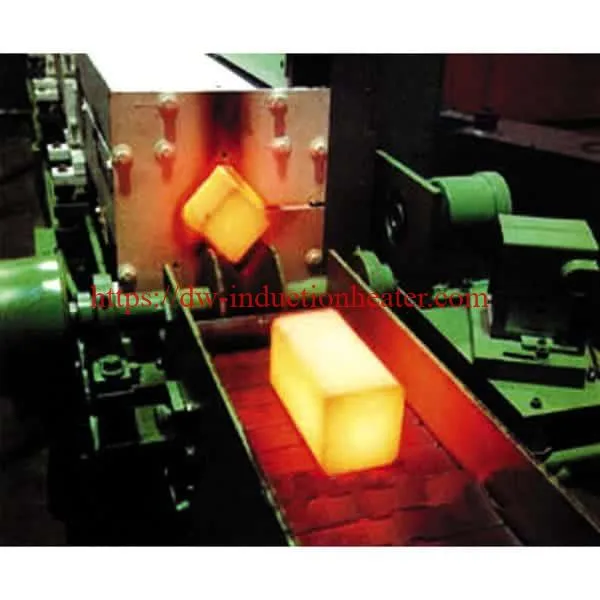

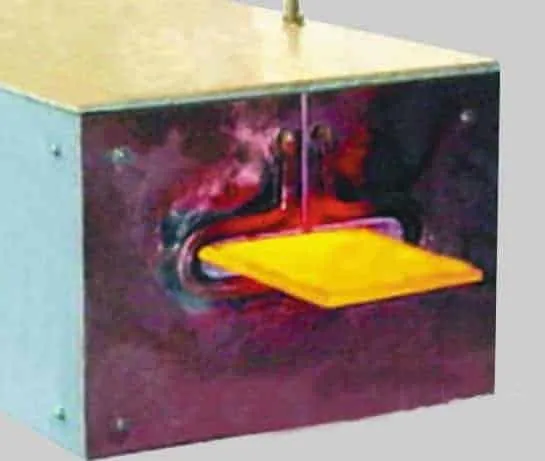

1. Jiil cusub oo saameyn ku yeelanaya tamarta keydinta IF haddii foornada soosaarka ay saameyn yar ku yeelato awooda, foojignaanta & dhalaalida waxtarka sare, isku mid ahaanta heerkulka, qiiqa oksijiinta oo yar, si fudud loo xakameeyo, saameynta kuleylka kuleylka ayaa wanaagsan iyo wixii la mid ah. HADDII nidaamka xakamaynta foornada la adeegsado iyadoo la adeegsanayo aragtida beddelidda awoodda AC-DC ee silikoon-koontaroolka ah, koontaroolka dijitaalka ah ee aan gudbinta lahayn, oo leh kalsooni sarreysa iyo soo noqnoqoshada hawlgalka badan ee awoodda ka-hortagga isku-dabaridka oo leh raad raaca otomaatiga ah, hababka shaqada ee aan lahayn faragelinta aadanaha, si toos ah ugu habboon culeyska awood. Xilliga xaadirka ah, korantada, wejiga la'aanta, awoodda ilaalinta cadaadiska biyaha oo aan ku filnayn taasoo u oggolaanaysa aaladaha qalad kasta oo dhaca inta lagu jiro hawlgalka ma dhaawici doono qaybaha, yaraynta isticmaalka qalabka iyo kharashyada dayactirka. Iyada oo kuleylka dhex gala, dhalaalayo, xirashada, daaweynta kuleylka, qallajinta, sida taageerida adeegsiga hal-dhaldhalaalka la sawiray. Waxay kordhin kartaa nidaamka ka jawaab celinta heerkulka, halabuurka heerkulka xirida-wareegga tooska ah ee toosinta: kordhinta heerkulka kala soocista ee ku xiran mashiinnada, si loo gaaro kaliya soo dir heerkulka foojignaanta u qalma ee xarunta shaqada. Intaa waxaa dheer iskudhafyo gaar ah, aqbal PLC ama "interface-man-machine interface", xakamaynta mashiinka warshadaha iyo nidaamka kululaynta si loo gaaro xakamaynta caqliga, oo ay weheliso aaladda xakamaynta heerkulka caqliga leh ee xakamaynta heerkulka saxda ah ee hirgelinta dhalashada & sameynta kulul.

2 foornada induction waxay ka kooban tahay:

HADDII AAD KA QAADAN KARO KORI KARTAA, Kombiyuutarrada, Foornada biyaha (aluminium ama birta), mishiinada (hydraulic) Qalabka kululeeyaha, bakhaariyaha biyaha, caaryeelka loo yaqaan "crucible", birta la jarayo,

3 taageeraya qalabka xulashada:

Qadka bedelka, qalabka korontada sare, nidaamka qaboojinta biyaha, baddelka foornada, qalabka faaruusta foornada, qalabka wax lagu xiro