Kordhinta Waxtarka iyo Waxqabadka Mashiinada Kuleyliyaha Induction

Sida tignoolajiyada kuleylka warshadaha, kululaynta induction waxa uu noqday mid aad u caan baxay sanadihii ugu danbeeyay. Tignoolajiyadan waxaa loo isticmaali karaa warshado kala duwan, oo ay ku jiraan baabuurta, hawada sare, biraha, iyo kuwa kale oo badan. Mashiinnada kuleylka ee induction waxay bixiyaan faa'iidooyin dhowr ah oo ku saabsan hababka kuleylka dhaqameed, oo ay ku jiraan kuleyl degdeg ah oo waxtar leh, hagaajinta habka xakamaynta, iyo isticmaalka tamarta oo yaraaday. Maqaalkan, waxaan ka wada hadli doonaa faa'iidooyinka mishiinnada kuleyliyaha induction, noocyada kala duwan ee qalabka la heli karo, iyo sida loo doorto mashiinka saxda ah ee baahidaada Horudhac Kuleyliyaha Induction Warshadaha

Kuleyliyaha kicinta waa nidaam adeegsada kicinta korantada si uu u kululeeyo birta ama walxaha kale ee wax dhaqaajiya. Kuleyliyaha induction-ka, goob birlabeedka beddelka ah waxaa dhaliya gariiradda induction, kaas oo dhex mara birta ama walxo kale Goobtan birlabeedka ahi waxa ay keentaa qulqulo qulqulaya birta, taas oo iyaduna keenta kulayl. Kuleylku si toos ah ayaa loo soo saaraa walxaha, taas oo ka dhigaysa kuleyliyaha induction aad uga dhaqso badan oo ka waxtar badan hababka kuleylka dhaqameed.

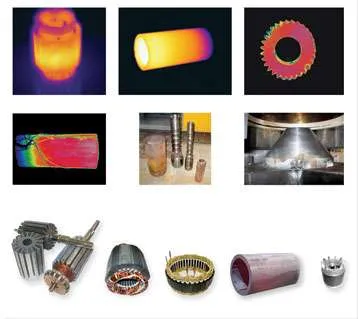

Kuleylinta soojiidashada waxaa loo isticmaalaa codsiyo kala duwan, oo ay ku jiraan naas-nuujinta, nuglaynta, qallafsanaanta, iyo dhalaalidda. Waxa kale oo loo isticmaali karaa in lagu dhejiyo, ku dhejinta, iyo isku-xidhka. Mashiinnada kuleyliyaha induction waxaa loo isticmaalaa warshado badan, oo ay ku jiraan baabuurta, hawada hawada, biraha, iyo kuwa kale oo badan.

Fahamka Mashiinnada Kuleyliyaha Induction

Mashiinnada kuleyliyaha induction waxay ka kooban yihiin dhowr qaybood, oo ay ku jiraan gariiradda induction, sahay koronto, iyo habka qaboojinta. Gariiradda induction waxa ay abuurtaa goob birlabeed ah taas oo keenta qulqulka qulqulka birta. Korontadu waxay bixisaa tamarta korantada ee loo beddelo goobta magnetic. Nidaamka qaboojinta waxaa loo isticmaalaa in lagu qaboojiyo gariiradda induction iyo qaybaha kale, maadaama kulaylka soo baxa inta lagu jiro habka uu noqon karo mid muhiim ah.

Waxaa jira laba nooc oo waaweyn oo ah mishiinnada kuleyliyaha induction: soo noqnoqoshada sare iyo inta jeer ee dhexdhexaadka ah. Mashiinnada soo noqnoqda ee sarreeya waxay ku shaqeeyaan tamar ka sarreeya 100 kHz, halka mashiinnada soo noqnoqda dhexdhexaadku ay ku shaqeeyaan inta u dhaxaysa 1 kHz iyo 100 kHz. Mashiinnada soo noqnoqda sare waxaa loo isticmaalaa qaybo yaryar iyo kululaynta dusha sare, halka mashiinnada soo noqnoqda dhexdhexaadka ah loo isticmaalo qaybo waaweyn iyo kululaynta bulk.

Faa'iidooyinka Mashiinnada Kuleylinta Induction

Mashiinnada kuleyliyaha induction waxay bixiyaan faa'iidooyin dhowr ah marka loo eego hababka kuleylka dhaqameed. Waa kuwan qaar ka mid ah faa'iidooyinka ugu muhiimsan:

- Kuleyliyaha degdega ah: Kuleyliyaha kicinta ayaa aad uga dhaqso badan hababka kuleyliyaha caadiga ah, maadaama kulaylku si toos ah ugu soo baxo walxaha. Tani waxay ka dhigan tahay in qaybaha si dhakhso ah loo kululayn karo loona qaboojin karo, taas oo hagaajin karta waxtarka habka oo yareyn karta wakhtiyada wareegga.

- Xakamaynta habka la wanaajiyay: Mashiinnada kuleyliyaha soo kicinta waxay bixiyaan xakamaynta heerkulka saxda ah, kaas oo u oggolaanaya natiijooyin joogto ah, oo la soo celin karo. Tani waxay si gaar ah muhiim ugu tahay warshadaha ay tayadoodu muhiim tahay, sida hawada sare iyo baabuurta.

- Isticmaalka tamarta oo la dhimay: Kuleyliyaha kicinta ayaa ka tamar badan ka waxtar badan hababka kuleyliyaha caadiga ah, maadaama kulaylku si toos ah ugu soo baxo walxaha. Tani waxay ka dhigan tahay in tamar yar ay lumiso, taas oo keeni karta kayd kharash badan oo waqti ah.

- Nadiifiye iyo ka badbaado badan: Kululaynta kicinta ma soo saarto wax sii daaya, taas oo ka dhigaysa mid ka nadiifsan oo ka badbaadsan hababka kuleylka dhaqameed. Waxa kale oo ay soo saartaa buuq yar iyo gariir, taas oo hagaajin karta xaaladaha shaqada ee shaqaalaha.

Noocyada Qalabka Kululaynta Induction

Waxaa jira dhowr nooc oo ah Qalabka kululeynta la-galinta la heli karo, oo ay ku jiraan:

- Kuleyliyeyaasha Induction: Kuwani waa mashiinnada kululaynta kicinta ee la qaadi karo oo loo isticmaalo kuleylinta qaybo yaryar ama meelaha degaanka ah.

- Foornooyinka Induction: Kuwani waa mashiinnada kululaynta kicinta ee waaweyn oo loo isticmaalo dhalaalinta biraha ama alaabada kale.

- Mashiinnada brazing induction: Kuwani waa mashiinada kuleyliyaha induction oo loo isticmaalo naxaasta ama alxanka.

- Mashiinnada qallafsanaanta: Kuwani waa mashiinnada kululaynta induction oo loo isticmaalo adkaynta qaybaha birta.

- Mashiinnada soo saarista induction: Kuwani waa mashiinnada kuleyliyaha induction oo loo isticmaalo in lagu tirtiro birta ama alaabta kale.

Waxaa jira laba qaybood oo waaweyn oo ah qalabka kulaylinta indutcion: mid waa awoodda wax soo saarka, mid kalena waa inta jeer.

Qoto dheer ee kulaylka gelitaanka workpiece waxay ku xiran tahay inta jeer, inta jeer ee sare, qoto dheer maqaarka qoto dheer; Inta jeer ee hoose, waa sii qoto dheeraanta dhexgalka.

Markaa waxaa muhiim ah in la doorto inta jeer ee mashiinka kuleylka induction si waafaqsan rabitaanka kuleylka si loo gaaro saameynta kuleylka ugu fiican.

Awoodda wax-soo-saarka ayaa go'aamisa xawaaraha kuleylka, awoodda waxaa lagu doortaa iyadoo loo eegayo miisaanka shaqada iyo heerkulka kuleylka iyo xawaaraha kuleylka ee la rabo.

Sidaa darteed, kuleyliyaha soo noqnoqda ee soo noqnoqda ayaa leh saameyn maqaarka gacmeed kaas oo si waxtar leh u leh qaybo yaryar. Kuleylka soo noqnoqda soo noqnoqda ee hooseeya wuxuu leeyahay saameyn qoto dheer oo maqaarka ah kaas oo si waxtar leh u leh qaybo waaweyn.

Mashiinada kuleyliyaha Induction waxay u qaybsan yihiin shan taxane oo waaweyn iyadoo loo eegayo inta jeer:

Soo noqnoqoshada dhexdhexaadka ah ee isbarbar-dhigga wareegga wareegga (abbr. MF): 1 - 20KHZ

Soo noqnoqoshada dhexdhexaadka ah ee Taxanaha wareegga oscillating (abbr. MFS taxane): 0.5-10KHZ

Taxanaha soo noqnoqda sare (abbr: HF taxane): 30-80KHZ

Taxanaha Frequency Super-audio (abbr. SF taxane): 8-40KHZ

Taxanaha Soo noqnoqda aadka u sarreeya (taxane abbr.UHF): 30-1100KHZ

| Noocyada | model | Awooda Max | Xilliga Oscillating | Xilliga hadda jira | danab gelin | danab shaqeeya | Wareegga shaqada |

| Taxanaha MF | Ji-15 | 15KW | 1-20KHZ | 23A | 3P 380V50Hz | 70-550V | 100% |

| Ji-25 | 25KW | 36A | |||||

| Ji-35 | 35KW | 51A | |||||

| Ji-45 | 45KW | 68A | |||||

| Ji-70 | 70KW | 105A | |||||

| Ji-90 | 90KW | 135A | |||||

| Ji-110 | 110KW | 170A | |||||

| Ji-160 | 160KW | 240A | |||||

| Taxanaha MFS | MFS-100 | 100KW | 0.5-10KHZ | 160A | 3P 380V50Hz | 342-430V | 100% |

| MFS-160 | 160KW | 250A | |||||

| MFS-200 | 200KW | 310A | |||||

| MFS-250 | 250KW | 380A | |||||

| MFS-300 | 300KW | 0.5-8KHZ | 460A | ||||

| MFS-400 | 400KW | 610A | |||||

| MFS-500 | 500KW | 760A | |||||

| MFS-600 | 600KW | 920A | |||||

| MFS-750 | 750KW | 0.5-6KHZ | 1150A | ||||

| MFS-800 | 800KW | 1300A | |||||

| Taxanaha HF | HF-04A | 4KW | 100-250KHZ | 15A | 1P 220V/50Hz | 180V-250V | 80% |

| HF-15A | 7KW | 30-100KHZ | 32A | 1P 220V/50Hz | 180V-250V | 80% | |

| HF-15AB | 7KW | 32A | |||||

| HF-25A | 15KW | 30-80KHZ | 23A | 3P 380V/50Hz | 340-430V | 100% | |

| HF-25AB | 15KW | 23A | |||||

| HF-40AB | 25KW | 38A | |||||

| HF-35AB | 35KW | 53A | |||||

| HF-45AB | 45KW | 68A | |||||

| HF-60AB | 60KW | 80A | |||||

| HF-70AB | 70KW | 105A | |||||

| HF-80AB | 80KW | 130A | |||||

| Taxanaha SF | SF-30A | 30KW | 10-40KHZ | 48A | 3P 380V/50Hz | 342-430V | 100% |

| SF-30ABS | 30KW | 48A | |||||

| SF-40ABS | 40KW | 62A | |||||

| SF-50ABS | 50KW | 75A | |||||

| SF-40AB | 40KW | 62A | |||||

| SF-50AB | 50KW | 75A | |||||

| SF-60AB | 60KW | 90A | |||||

| SF-80AB | 80KW | 125A | |||||

| SF-100AB | 100KW | 155A | |||||

| SF-120AB | 120KW | 185A | |||||

| SF-160AB | 160KW | 8-30KHZ | 245A | ||||

| SF-200AB | 200KW | 310A | |||||

| SF-250AB | 250KW | 380A | |||||

| SF-300AB | 300KW | 455A | |||||

| Taxanaha UHF | UHF-05AB | 5KW | 0.5-1.1MHZ | 15A | 1P 220V/50Hz | 180V-250V | 80% |

| UHF-06A-I | 6.6KW | 200-500KHZ | 30A | 1P 220V/50Hz | 180V-250V | 80% | |

| UHF-06A-II | 6.6KW | 200-700KHZ | |||||

| UHF-06A/AB-III | 6KW | 0.5-1.1MHZ | |||||

| UHF-10A-I | 10KW | 50-300KHZ | 15A | 3P 380V/50Hz | 342-430V | 100% | |

| UHF-10A-II | 10KW | 200-500KHZ | 45A | 1P 220V/50Hz | 180-250V | 80% | |

| UHF-20AB | 20KW | 50-250KHZ | 30A | 3P 380V/50Hz | 342-430V | 100% | |

| UHF-30AB | 30KW | 50-200KHZ | 45A | ||||

| UHF-40AB | 40KW | 60A | |||||

| UHF-60AB | 60KW | 30-120KHZ | 90A | ||||

Marka laga reebo qalabka kuleyliyaha wareegga Analog, HLQ waxay leeyihiin DSP Mashiinnada Kuleylinta Soo-saarka Xakamaynta Dijital ah oo Buuxa:

| Noocyada | model | Awooda Max | Xilliga Oscillating | Xilliga hadda jira | danab gelin | |

| DSP buuxa ee soo noqnoqda maqalka sare ee dhijitaalka ah | D-SF160 | 160KW | 2-50Khz | 240A | 3P 380V50Hz | |

| D-SF200 | 200KW | 300A | ||||

| D-SF250 | 250KW | 380A | ||||

| D-SF300 | 300KW | 450A | ||||

| D-SF350 | 350KW | 530A | ||||

| D-SF400 | 400KW | 610A | ||||

| D-SF450 | 450KW | 685A | ||||

| D-SF500 | 500KW | 760A | ||||

| D-SF550 | 550KW | 835A | ||||

| D-SF600 | 600KW | 910A | ||||

| DSP buuxa ee dhijitaalka ah inta jeer ee sare | D-HF160 | 160KW | 50-100Khz | 240A | 3p 380V50Hz | |

| D-HF200 | 200KW | 300A | ||||

| D-HF250 | 250KW | 380A | ||||

| D-HF300 | 300KW | 450A | ||||

| D-HF350 | 350KW | 530A | ||||

| D-HF400 | 400KW | 610A | ||||

| D-HF450 | 450KW | 685A | ||||

| D-HF500 | 500KW | 760A | ||||

| D-HF550 | 550KW | 835A | ||||

| D-HF600 | 600KW | 910A | ||||

| DSP buuxa oo dhijitaal ah oo soo noqnoqda Ultrahigh | D-UF100 | 100KW | 100-150Khz | 150A | 3p 380V50Hz | |

| D-UF160 | 160KW | 240A | ||||

| D-UF200 | 200KW | 300A | ||||

| Soo noqnoqoshada dhijitaalka ah ee buuxa ee DSP | D-MFS100-2000 | 100-2000kw | 1-10kz | 3p 380V,50Hz | ||

Waxyaalaha ay tahay in la tixgeliyo marka la dooranayo Mashiinka Kuleylinta Induction

Markaad dooranayso mishiinka kuleyliyaha induction, waxaa jira dhowr arrimood oo ay tahay in la tixgeliyo, oo ay ku jiraan:

- Nooca alaabta iyo dhumucda: Qalabka kala duwan waxay u baahan yihiin waqtiyo kuleyl iyo wareegyo kala duwan. Dhumucda maaddadu waxay sidoo kale saameyn doontaa wakhtiga kuleylka.

- Shuruudaha kuleyliyaha: heerkulka iyo muddada habka kuleylka waxay ku xirnaan doontaa codsiga.

- Cabbirka qaybta iyo qaabka: Cabbirka iyo qaabka qaybta ayaa go'aamin doona nooca iyo cabbirka gariiradda induction ee loo baahan yahay.

- Shuruudaha korontada: Korontadu waxay ku xirnaan doontaa cabbirka iyo nooca mashiinka, iyo sidoo kale shuruudaha kuleylka.

Sida loo doorto Qaybta Kululaynta ee Saxda ah

Si aad u dooratid mashiinka kuleyliyaha kuleyliyaha saxda ah ee baahidaada, waa muhiim inaad tixgeliso arrimaha kor ku xusan. Waa inaad sidoo kale tixgelisaa sumcadda soo-saaraha, qiimaha mishiinka, iyo helitaanka qaybaha qalabka iyo taageerada farsamada.

Waxa kale oo muhiim ah in la doorto mashiinka ay fududahay in la isticmaalo oo la dayactiro. Mashiinnada qaarkood waxay u baahan yihiin dayactir ka badan kuwa kale, tani waxay saameyn kartaa qiimaha guud ee lahaanshaha.

Qiimaha Mashiinnada Kuleyliyaha Induction

Qiimaha makiinadaha kuleyliyaha induction aad bay u kala duwanaan karaan iyadoo ku xiran xajmiga, nooca, iyo soo saaraha. Kuleyliyeyaasha la qaadan karo waxay ku kici karaan wax yar ilaa dhowr boqol oo doolar, halka foornooyinka wax-gelinta ee waaweyn ay ku kici karaan boqolaal kun oo doolar.

Waa muhiim in la tixgeliyo maaha oo kaliya kharashka hore ee mashiinka, laakiin sidoo kale kharashka lahaanshaha waqti ka dib. Tan waxaa ku jira kharashka korontada, dayactirka, iyo dayactirka.

Dayactirka iyo Dayactirka Qalabka Kuleylinta Induction

Dayactirka joogtada ah ayaa muhiim u ah si loo hubiyo cimri dhererka iyo waxqabadka mashiinnada kuleyliyaha induction. Tan waxaa ka mid ah nadiifinta gariiradda induction, hubinta sahayda korontada iyo nidaamka qaboojinta, iyo ka-fiirinta mashiinka calaamadaha jeexan iyo jeexjeexa.

Haddii dayactir loo baahan yahay, waxaa muhiim ah in lala shaqeeyo farsamoyaqaan aqoon leh oo khibrad u leh mishiinnada kuleyliyaha induction. Tani waxay hubin doontaa in dayactirka loo sameeyay si sax ah oo badbaado leh.

Gabagabo: Mustaqbalka Tiknoolajiyada Kuleylinta Soo-gelinta

Tiknoolajiyada kuleyliyaha kicinta ayaa soo martay waddo dheer sannadihii la soo dhaafay, waxayna u badan tahay inay sii socoto horumarinta iyo horumarinta mustaqbalka. Maaddaama warshaduhu ay raadinayaan inay wanaajiyaan hufnaanta oo ay yareeyaan kharashaadka, mashiinnada kuleyliyaha induction waxay ciyaari doonaan door muhiim ah oo sii kordheysa.

Haddii aad ka fekereyso mashiinka kuleyliyaha induction ee ganacsigaaga, waa muhiim inaad doorato mashiinka buuxinaya baahiyahaaga gaarka ah iyo shuruudahaaga. Markaad tixgeliso arrimaha kor ku xusan oo aad la shaqeyso soo saaraha iyo farsamayaqaan sumcad leh, waxaad xaqiijin kartaa inaad ka faa'iidaysato inta ugu badan ee mashiinka kuleyliyahaaga.