Kuleyliyeyaasha dareeraha kuleylka ee Induction-Kuleyliyeyaasha saliidda wareejinta kulaylka

Description

Kuleyliyeyaasha dareeraha kuleylka ee Induction waa habab kuleyl oo horumarsan oo isticmaala mabaadi'da soo saarida elektromagnetic si toos ah loo kululeeyo dareeraha kulaylka wareega.

Kuleyliyeyaasha dareeraha kulaylka induction Waxay u soo ifbaxday sidii tignoolajiyada rajo-gelinta leh ee qaybaha warshadaha kala duwan, iyagoo bixiya faa'iidooyin badan marka loo eego hababka kuleylka dhaqameed. Warqadani waxay sahamisaa mabaadi'da, naqshadeynta, iyo codsiyada kuleyliyeyaasha dareeraha kulaylka ee induction, oo muujinaya faa'iidooyinkooda iyo caqabadaha iman kara. Iyada oo loo marayo falanqayn dhamaystiran oo ku saabsan waxtarkooda tamarta, xakamaynta heerkulka saxda ah, iyo hoos u dhigista shuruudaha dayactirka, daraasaddan ayaa muujinaysa sareynta tignoolajiyada kuleylinta induction ee hababka warshadaha casriga ah. Intaa waxaa dheer, daraasadaha kiisaska iyo falanqaynta isbarbardhigga ayaa bixiya aragtiyo wax ku ool ah oo ku saabsan hirgelinta guusha leh ee kuleyliyeyaasha dareeraha kuleylka ee dhirta kiimikada iyo warshadaha kale. Warqaddu waxay ku soo gabagabaynaysaa dood ku saabsan rajada mustaqbalka iyo horumarka tignoolajiyadan, iyada oo xoogga saaraysa awooddeeda wax-ku-oolnimo iyo hal-abuurnimo dheeraad ah.

Halbeegga Technical

| Kuleyliyaha dareeraha kuleylka ee Induction | Kuleyliyaha saliidda kuleylka ee Induction | ||||||

| Faahfaahinta Moodeelka | DBOB-80 | DBOB-100 | DBOB-150 | DBOB-300 | DBOB-600 | |

| Cadaadiska naqshadeynta (MPa) | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | |

| Cadaadiska shaqada (MPa) | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | |

| Awood la qiimeeyay (KW) | 80 | 100 | 150 | 300 | 600 | |

| Qiimeeyay kan hadda (A) | 120 | 150 | 225 | 450 | 900 | |

| Korantada la qiimeeyay (V) | 380 | 380 | 380 | 380 | 380 | |

| sax | ± 1 ° C | |||||

| Kala duwanaanta heerkulka (℃) | 0-350 | 0-350 | 0-350 | 0-350 | 0-350 | |

| Waxqabadka kuleylka | 98% | 98% | 98% | 98% | 98% | |

| Madaxa bamgare | 25/38 | 25/40 | 25/40 | 50/50 | 55/30 | |

| socodka bamka | 40 | 40 | 40 | 50/60 | 100 | |

| motor Power | 5.5 | 5.5/7.5 | 20 | 21 | 22 | |

Hordhac

1.1 Dulmarka tignoolajiyada kuleylinta induction

Kuleyliyaha kicinta waa habka kuleyliyaha aan lala xiriirin kaas oo ka faa'iideysanaya kicinta korantada si ay u abuurto kulayl gudaha walax la beegsanayo. Farsamadani waxay heshay fiiro gaar ah sanadihii ugu dambeeyay sababtoo ah awoodda ay u leedahay inay bixiso xalal kulul oo degdeg ah, sax ah, oo hufan. Kuleyliyaha kicinta wuxuu ka helaa codsiyada hababka warshadaha kala duwan, oo ay ku jiraan daaweynta birta, alxanka, iyo kuleylka dareeraha kuleylka (Rudnev et al., 2017).

1.2 Mabda'a kuleyliyaha dareeraha kulaylka induction

Kuleyliyeyaasha dareeraha kuleylka ee Induction waxay ku shaqeeyaan mabda'a soo-saarka korantada. Dhaqdhaqaaqa beddelka ah ayaa la dhex maraa gariiradda, abuurista goob birlab ah oo kicisa qulqulka qulqulka ee walxaha bartilmaameedka ah. Dhaqdhaqaaqyadan qallafsan waxay dhaliyaan kulayl gudaha walxaha iyada oo loo marayo kuleylinta Joule (Lucia et al., 2014). Marka la eego kuleyliyeyaasha dareeraha kuleylka ee induction, walxaha bartilmaameedku waa dareeraha kulaylka, sida saliidda ama biyaha, kaas oo la kululeeyo marka ay dhex marto gariiradda induction.

1.3 Faa'iidooyinka ku jira hababka kuleylka dhaqameed

Kuleyliyeyaasha dareeraha kulaylka ee induction waxay bixiyaan faa'iidooyin dhowr ah hababka kuleylka dhaqameed, sida kuleyliyeyaasha gaaska ku shaqeeya ama korontada. Waxay bixiyaan kuleyl degdeg ah, xakameynta heerkulka saxda ah, iyo waxtarka tamarta sare (Zinn & Semiatin, 1988). Intaa waxaa dheer, kuleyliyeyaasha kicinta waxay leeyihiin naqshad isku dhafan, shuruudaha dayactirka oo yaraaday, iyo cimriga qalabka oo dheer marka loo eego dhiggooda dhaqameed.

Naqshadeynta iyo Dhismaha Kuleyliyeyaasha dareeraha kulaylka ee Induction

2.1 Qaybaha muhiimka ah iyo hawlahooda

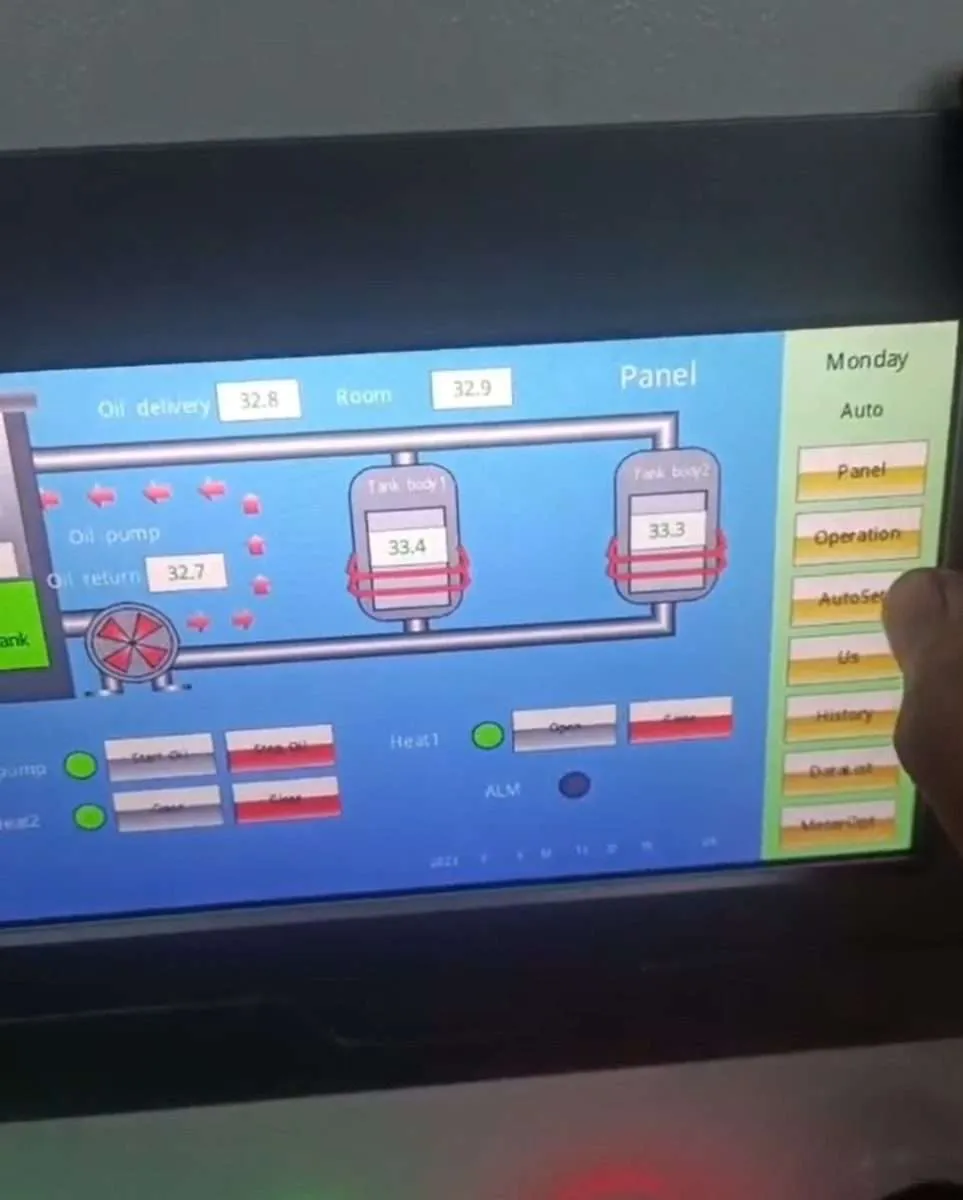

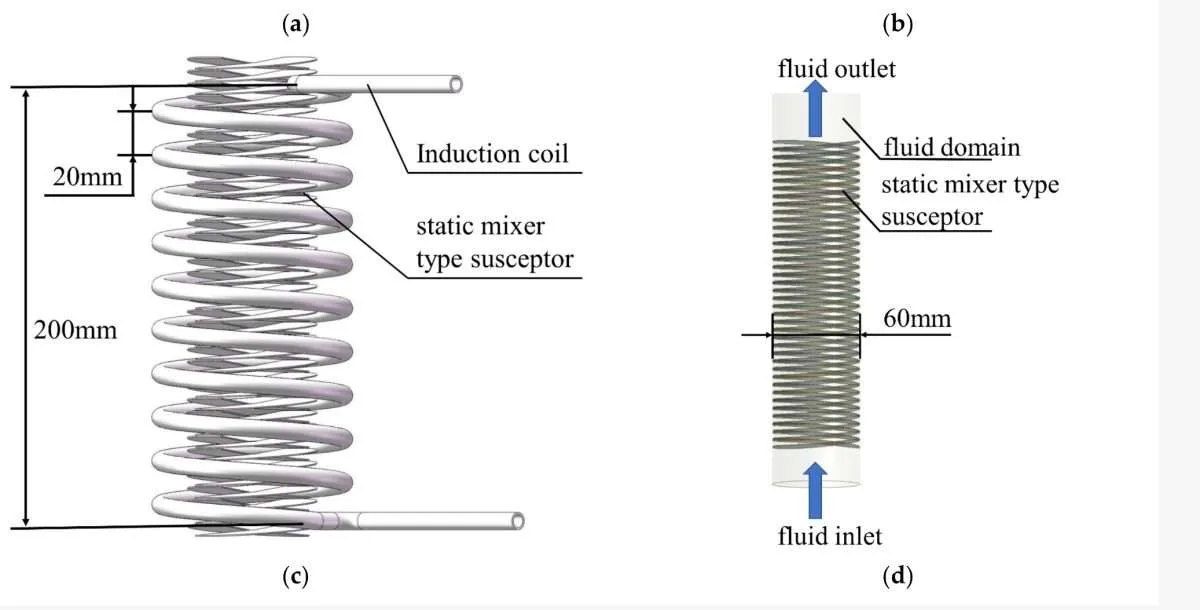

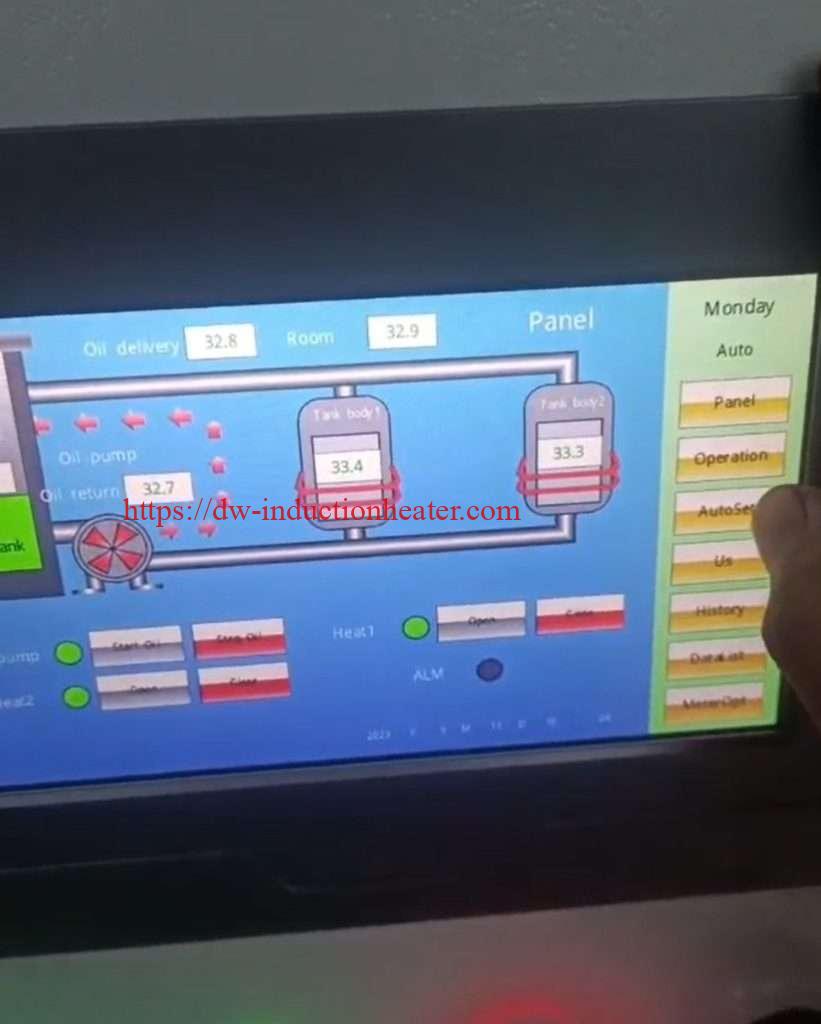

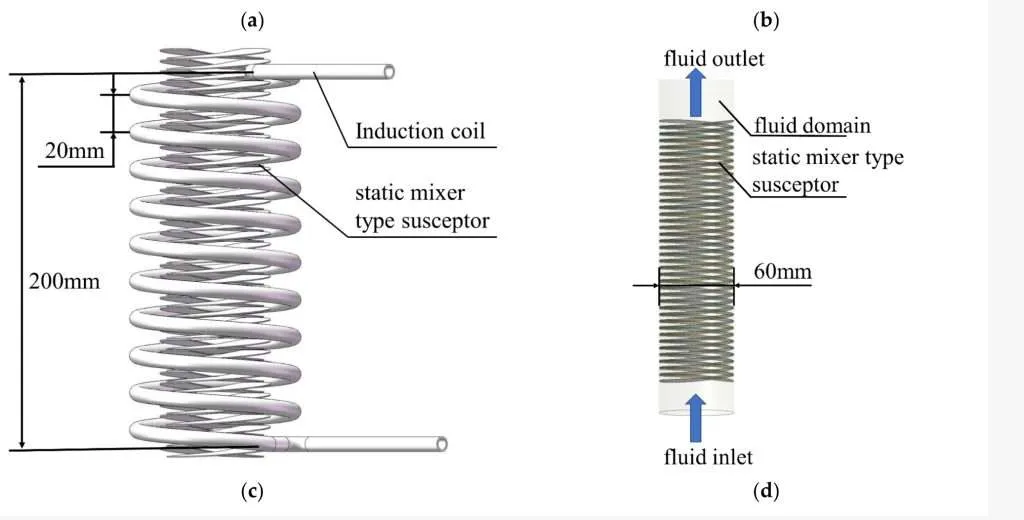

Qaybaha ugu muhiimsan ee kuleyliyaha dareeraha kulaylka ee induction waxaa ka mid ah gariiradda induction, sahay koronto, nidaamka qaboojinta, iyo unugga kantaroolka. Gariiradda induction-ka ayaa mas'uul ka ah soo saarida goobta birlabeedka ee keenta kulaylka dareeraha kulaylka. Korontadu waxay siisaa tamarta beddelka ah ee gariiradda, halka nidaamka qaboojinta uu ilaalinayo heerkulka ugu fiican ee qalabka. Cutubka kantaroolku wuxuu nidaamiyaa soo-gelinta tamarta wuxuuna la socdaa cabbirrada nidaamka si loo hubiyo hawlgal ammaan ah oo hufan (Rudnev, 2008).

2.2 Qalabka loo isticmaalo dhismaha

Qalabka loo isticmaalo dhismaha kuleyliyaha dareeraha kulaylka induction waxaa lagu doortaa iyadoo lagu salaynayo korantada, magnetic, iyo kuwa kulaylka. Gariiradda induction caadi ahaan waxaa laga sameeyaa naxaas ama aluminium, kuwaas oo leh korantada korantada sare waxayna si hufan u dhalin kartaa goobta birlabeedka loo baahan yahay. Weelka haynta dareeraha kulaylka waxa uu ka samaysan yahay maaddooyin leh kulayl wanaagsan iyo iska caabin daxalka, sida birta ama titanium (Goldstein et al., 2003).

2.3 Tixgelinta naqshadeynta waxtarka iyo adkeysiga

Si loo hubiyo waxtarka ugu wanaagsan iyo cimri dhererka, dhowr tixgalin naqshadeed waa in la tixgeliyaa marka la dhisayo kuleyliyeyaasha dareeraha kuleylka ee induction. Kuwaas waxaa ka mid ah joomatari gariiradda induction, inta jeer ee hadda beddelka ah, iyo sifooyinka dareeraha kulaylka. Joomatari gariiradda waa in la hagaajiyaa si loo kordhiyo waxtarka isku-xidhka ee u dhexeeya goobta birlabeedka iyo shayga la beegsanayo. Inta jeer ee tamarta beddelka ah waa in lagu doortaa iyadoo lagu salaynayo heerka kuleylka la rabo iyo sifooyinka dareeraha kulaylka. Intaa waxaa dheer, nidaamka waa in loo qaabeeyaa si loo yareeyo khasaaraha kulaylka iyo hubinta kuleylinta isku midka ah ee dareeraha (Lupi et al., 2017).

Codsiyada warshadaha kala duwan

3.1 Habaynta kiimikaad

Kuleyliyeyaasha dareeraha kuleylka ee Induction waxay ka helaan codsiyo ballaaran warshadaha warshadaynta kiimikada. Waxa loo isticmaalaa kulaylinta weelasha falcelinta, tiirarka jeexjeexa, iyo kulaylka beddelayaasha. Xakamaynta heerkulka saxda ah iyo kuleyliyaha degdega ah ee kuleyliyeyaasha kicinta ayaa awood u siinaya heerarka falcelinta degdega ah, tayada badeecada oo hagaagtay, iyo isticmaalka tamarta oo yaraatay (Mujumdar, 2006).

3.2 Soo saarista cuntada iyo cabitaanka

Warshadaha cuntada iyo cabitaanka, kuleyliyeyaasha dareeraha kulaylka induction ayaa loo shaqeeyaa daaqsinka, jeermiska, iyo hababka karinta. Waxay bixiyaan kuleyl isku mid ah iyo xakamaynta heerkulka saxda ah, hubinta tayada badeecada iyo badbaadada joogtada ah. Kuleyliyeyaasha kicinta waxay sidoo kale bixiyaan faa'iidada wasakheynta la dhimay iyo nadiifinta sahlan marka loo eego hababka kuleylka dhaqameed (Awuah et al., 2014).

3.3 Wax soo saarka dawooyinka

Kuleyliyeyaasha dareeraha kuleylka ee Induction waxaa loo isticmaalaa warshadaha dawooyinka habab kala duwan, oo ay ku jiraan nadiifinta, qalajinta, iyo jeermiska. Xakamaynta heerkulka saxda ah iyo awoodaha kuleyliyaha degdega ah ee kuleyliyeyaasha kicinta ayaa muhiim u ah ilaalinta sharafta iyo tayada alaabta dawooyinka. Intaa waxaa dheer, naqshadaynta isku dhafan ee kuleyliyeyaasha kicinta waxay u oggolaaneysaa isdhexgalka fudud ee khadadka wax soo saarka ee jira (Ramaswamy & Marcotte, 2005).

3.4 Caagadaha iyo farsamaynta caagga

Warshadaha balaastikada iyo caagga ah, kuleyliyeyaasha dareeraha kulaylka induction waxaa loo isticmaalaa qaabaynta, soo saarista, iyo hababka daaweynta. Kuleyliyaha isku midka ah iyo kantaroolka heerkulka saxda ah ee ay bixiyaan kuleyliyeyaasha induction waxay xaqiijiyaan tayada badeecada joogtada ah iyo hoos u dhaca waqtiyada wareegyada. Kuleylka soo-gelinta ayaa sidoo kale awood u siinaya bilawga degdega ah iyo isbeddellada, hagaajinta guud ahaan waxtarka wax-soo-saarka (Goodship, 2004).

3.5 Warshada waraaqaha iyo saxarka

Kuleyliyeyaasha dareeraha kulaylka ee induction waxay ka helaan codsiyada waraaqaha iyo warshadaha saxarada ee qalajinta, kululaynta, iyo hababka uumiga. Waxay bixiyaan kuleyl hufan oo isku mid ah, yareynta isticmaalka tamarta iyo hagaajinta tayada alaabta. Naqshadaynta isku-dhafka ah ee kuleyliyeyaasha kicinta waxay sidoo kale u oggolaaneysaa is-dhexgalka fudud ee warshadaha waraaqaha ee jira (Karlsson, 2000).

3.6 Codsiyada kale ee suurtagalka ah

Marka laga reebo warshadaha aan kor ku soo sheegnay, kuleyliyeyaasha dareeraha kulaylka induction waxay awood u leeyihiin codsiyada qaybaha kale ee kala duwan, sida farsamaynta dharka, daaweynta qashinka, iyo hababka tamarta la cusboonaysiin karo. si loo raadiyo xalal tamar-ku-ool ah oo sax ah, baahida loo qabo kuleyliyeyaasha dareeraha kulaylka ee induction ayaa la filayaa inay koraan.

Faa'iidooyinka iyo Faa'iidooyinka

4.1 Hufnaanta tamarta iyo kaydinta kharashka

Mid ka mid ah faa'iidooyinka aasaasiga ah ee kuleyliyeyaasha dareeraha kulaylka induction waa waxtarkooda sare ee tamarta. Kuleyliyaha induction wuxuu si toos ah u dhaliyaa kulayl gudaha walxaha bartilmaameedka ah, isagoo yareynaya khasaaraha kulaylka ee agagaarka. Tani waxay keenaysaa kaydka tamarta ilaa 30% marka la barbar dhigo hababka kuleylka dhaqameed (Zinn & Semiatin, 1988). Waxtarka tamarta ee la hagaajiyay waxay u tarjumeysaa hoos u dhaca kharashaadka hawlgalka iyo saameynta deegaanka oo hooseysa.

4.2 Xakamaynta heerkulka saxda ah

Kuleyliyeyaasha dareeraha kuleylka ee Induction waxay bixiyaan xakamaynta heerkulka saxda ah, awood u siinaya nidaaminta saxda ah ee habka kuleylka. Jawaabta degdega ah ee kuleyliyaha kicinta waxay u oggolaaneysaa isbeddel degdeg ah oo ku saabsan isbeddelka heerkulka, hubinta tayada badeecada joogtada ah. Xakamaynta heerkulka saxda ah ayaa sidoo kale yaraynaysa khatarta kulaylka ama kulaylka hoostiisa, taas oo u horseedi karta cilladaha alaabta ama khataraha badbaadada (Rudnev et al., 2017).

4.3 Kuleyl degdeg ah iyo hoos u dhac ku yimid wakhtiga habaynta

Kuleyliyaha kicinta wuxuu bixiyaa kuleyl degdeg ah walxaha la beegsanayo, si weyn u yareynaya waqtiyada wax-qabadka marka loo eego hababka kuleylka dhaqameed. Heerarka kuleyliyaha degdega ah ayaa awood u leh waqtiyada bilowga gaaban iyo isbeddellada degdega ah, hagaajinta guud ahaan waxtarka wax soo saarka. Wakhtiga habaynta ee la dhimay ayaa sidoo kale horseedaysa korodhka wax soo saarka iyo wax soo saarka sare (Lucia et al., 2014).

4.4 tayada alaabta oo la hagaajiyay iyo joogtaynta

Kuleyliyaha isku midka ah iyo xakamaynta heerkulka saxda ah ee ay bixiso kuleyliyeyaasha dareeraha kulaylka induction waxay keenaysaa tayada badeecada oo soo hagaagtay iyo joogtaynta. Awoodaha kuleyliyaha degdega ah iyo qaboojinta ee kuleyliyeyaasha kicinta waxay yareeyaan khatarta kuleylka kulaylka waxayna xaqiijiyaan sifooyinka isku midka ah dhammaan alaabta. Tani waxay si gaar ah muhiim ugu tahay warshadaha sida habaynta cuntada iyo dawooyinka, halkaas oo tayada iyo badbaadada alaabadu ay muhiim tahay (Awuah et al., 2014).

4.5 Dayactirka oo yaraaday iyo cimriga qalabka oo dheer

Kuleyliyeyaasha dareeraha kuleylka ee kicinta ayaa hoos u dhigay shuruudaha dayactirka marka loo eego hababka kuleylka dhaqameed. Maqnaanshaha qaybaha dhaqaaqa iyo dabeecadda aan xidhiidhka ahayn ee kuleyliyaha kicinta waxay yareeyaan jeexjeexa iyo dillaaca qalabka. Intaa waxaa dheer, naqshadeynta isku-dhafka ah ee kuleyliyeyaasha kicinta waxay yareyneysaa halista daadinta iyo daxalka, taasoo sii kordhineysa cimriga qalabka. Shuruudaha dayactirka ee la dhimay ayaa keenaya hoos u dhaca kharashka iyo dayactirka (Goldstein et al., 2003).

Caqabadaha iyo Horumarka Mustaqbalka

5.1 Kharashyada maalgashiga bilowga ah

Mid ka mid ah caqabadaha la xidhiidha qaadashada kuleyliyeyaasha dareeraha kuleylka ee induction waa kharashka maalgashiga bilowga ah. Qalabka kuleyliyaha induction guud ahaan wuu ka qaalisan yahay hababka kuleylinta dhaqanka. Si kastaba ha ahaatee, faa'iidooyinka muddada-dheer ee waxtarka tamarta, dayactirka oo yaraada, iyo tayada wax soo saarka oo la hagaajiyay waxay inta badan caddeeyaan maalgelinta bilowga ah (Rudnev, 2008).

5.2 Tababarka hawl wadeenada iyo tixgelinta badbaadada

Hirgelinta kuleyliyaha dareeraha kulaylka induction waxay u baahan tahay tabobar sax ah oo hawl wadeen ah si loo xaqiijiyo hawlgal badbaado leh oo hufan. Kuleylinta soo kicinta waxay ku lug leedahay qulqulo koronto oo aad u sarreeya iyo goobo birlab ah oo xooggan, kuwaas oo keeni kara khataro badbaado haddii aan si habboon loo maamulin. Tababar ku filan iyo borotokool badbaado waa in la diyaariyaa si loo yareeyo khatarta shilalka loona hubiyo u hoggaansanaanta xeerarka khuseeya (Lupi et al., 2017).

5.3 Isku-dhafka nidaamyada jira

Isku dhafka kuleyliyeyaasha dareeraha kuleylka ee induction ee hababka warshadaha ee jira waxay noqon kartaa caqabad. Waxa laga yaabaa inay u baahato wax ka beddelka kaabayaasha jira iyo nidaamyada xakamaynta. Qorshaynta saxda ah iyo isuduwidda ayaa lagamamaarmaan u ah si loo xaqiijiyo is dhexgalka aan kala go 'lahayn loona yareeyo carqaladaynta hawlgallada socda (Mujumdar, 2006).

5.4 Suuragalnimada horumarinta iyo hal-abuurka dheeraadka ah

In kasta oo horumarka tignoolajiyada kuleylinta induction la sameeyay, haddana waxaa jira karti dheeraad ah oo la sii wanaajinayo iyo hal-abuurnimo. Cilmi-baadhista socota waxay diiradda saartaa hagaajinta hufnaanta, isku halaynta, iyo kala-duwanaanta kuleyliyeyaasha dareeraha kulaylka ee induction. Meelaha xiisaha leh waxaa ka mid ah horumarinta agabyada horumarsan ee gariirada soo-gelinta, hagaajinta joomatariyada gariiradda, iyo is-dhexgalka nidaamyada xakamaynta smart ee kormeerka iyo hagaajinta waqtiga-dhabta ah (Rudnev et al., 2017).

Studies Case

6.1 Hirgelinta guusha leh ee warshad kiimikaad

Daraasad uu sameeyay Smith et al. (2019) baadhay hirgelinta guusha leh ee kuleyliyaha dareeraha kulaylka ee warshadaynta kiimikada. Warshadu waxay ku bedeshay kuleyliyaheedii caadiga ahaa ee gaaska lagu shido kuleyliyaha induction si loo habeeyo kala-bax. Natiijooyinka waxay muujiyeen hoos u dhac 25% isticmaalka tamarta, kororka 20% awoodda wax soo saarka, iyo 15% hagaajinta tayada alaabta. Muddada dib-u-celinta ee maalgelinta bilowga ah waxaa loo xisaabiyay inay ka yar tahay laba sano.

6.2 Falanqaynta isbarbardhigga hababka kuleylka dhaqameed

Falanqaynta isbarbardhigga ah ee Johnson iyo Williams (2017) waxay qiimeeyeen waxqabadka kuleyliyeyaasha dareeraha kulaylka ee ka dhanka ah kuleyliyeyaasha caabbinta korantada ee dhaqameed ee goobta diyaarinta cuntada. Daraasadu waxay ogaatay in kuleyliyeyaasha kicinta ay isticmaaleen 30% tamar ka yar isla markaana ay lahaayeen 50% cimriga qalabka oo dheer marka loo eego kuleyliyeyaasha iska caabbinta korantada. Xakamaynta heerkulka saxda ah ee ay bixiso kuleyliyeyaasha kicinta waxay sidoo kale keentay hoos u dhac 10% ah cilladaha alaabta iyo 20% korodhka waxtarka qalabka guud (OEE).

Ugu Dambeyn

7.1 Qodobbada muhiimka ah oo kooban

Warqadani waxay sahamisay horumarka iyo adeegsiga kuleyliyaha dareeraha kulaylka induction ee warshadaha casriga ah. Mabaadi'da, tixgelinta naqshadeynta, iyo faa'iidooyinka tignoolajiyada kuleylinta kicinta ayaa si faahfaahsan looga hadlay. Kala duwanaanshaha kuleyliyaha dareeraha kulaylka induction ee warshado kala duwan, oo ay ku jiraan farsamaynta kiimikada, soosaarka cuntada iyo cabitaanka, dawooyinka, balaastikada iyo caagga, iyo waraaqaha iyo saxarka, ayaa la iftiimiyay. Caqabadaha laxidhiidha qaadashada kuleylinta kicinta, sida kharashyada maalgashiga bilowga ah iyo tababarka hawlwadeenada, ayaa sidoo kale wax laga qabtay.

7.2 Muuqaalka korsashada iyo horumarka mustaqbalka

Daraasadaha kiisaska iyo falanqaynta isbarbardhigga ee lagu soo bandhigay warqaddan ayaa muujinaya waxqabadka sare ee kuleyliyeyaasha dareeraha kuleylka ee induction marka loo eego hababka kuleylka dhaqameed. Faa'iidooyinka waxtarka tamarta, xakamaynta heerkulka saxda ah, kuleyl degdeg ah, tayada alaabta oo la hagaajiyay, iyo dayactirka la dhimay ayaa ka dhigaya kuleyliyaha induction doorasho soo jiidasho leh ee hababka warshadaha casriga ah. Sida warshaduhu sii wadaan inay mudnaanta siiyaan waaritaanka, hufnaanta, iyo tayada alaabta, qaadashada kuleyliyaha dareeraha kulaylka induction ayaa la filayaa inuu kordho. Horumarka dheeraadka ah ee alaabta, hagaajinta naqshadaynta, iyo nidaamyada xakamaynta ayaa kicin doona horumarinta mustaqbalka ee tignoolajiyadan, furitaanka fursadaha cusub ee codsiyada kuleylka warshadaha.